【別注】DIMAGLIA CRAVATTE×TOMORROWLAND カシミヤシルク スカーフ

(税込) 送料込み

商品の説明

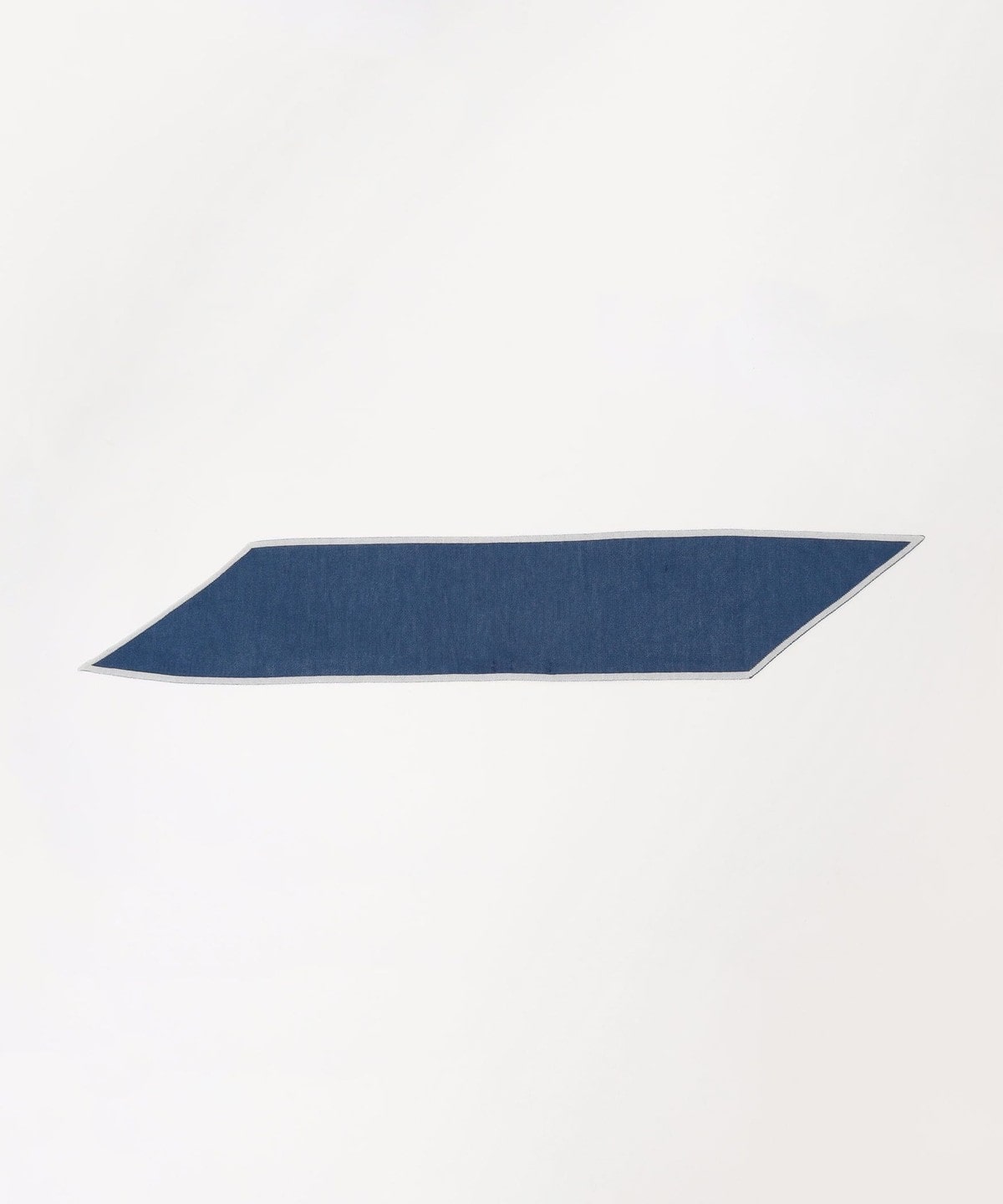

柔らかな巻き心地とコーディネートに溶け込んでくれるニットスカーフ。

巻きやすさを考慮した形を1から別注で作成し、素材もラグジュアリーな素材を採用しています。

■素材

イタリア<CARIAGGI(カリアッジ)>社のカシミアシルクの素材を採用。

同社のカシミアは繊維長が細く長いのが特徴で、そこにシルクを高度な紡績技術を用いることで柔らかく滑らかな風合いを実現。

■デザイン

結び目が綺麗に収まるようなひし形を一から別注にて作成。

巻いた際の結び目、コーディネートへの収まりを考慮した形は、幅広いコーディネートに溶け込んでくれる万能性が魅力。

配色を変えたリバーシブルになっており、コーディネートに合わせて使い分けることもできます。

<DIMAGLIEA CRAVATTE(ディマリア クラヴァッテ)>

イタリアのシルクの一大産地のコモに本社を構え、ニットタイを専門としたブランド。伝統的な手仕事と新たな機械の技術を融合させたコレクションを展開。高級素材の扱いにも長け、丁寧な手仕事によるクオリティーは、ビッグメゾンのOEMを請け負っていることからも見てとれます。

確かなクオリティーに裏付けた技術力から多くのブランドからの支持を集めています。

2022AW商品

店舗にお問い合わせの際は、下記の商品番号をお申し付けください。

商品番号:65-16-24-16001

- 原産国

- イタリア

- 素材

- カシミヤ70% シルク30%

- 特徴

- 無地

- 関連カテゴリー

- 財布/小物

- バンダナ/スカーフ

- 性別タイプ

- メンズ

別注】Dimaglia Cravatte×TOMORROWLAND カシミヤシルク スカーフ

別注】Dimaglia Cravatte×TOMORROWLAND カシミヤシルク スカーフ

別注】Dimaglia Cravatte×TOMORROWLAND カシミヤシルク スカーフ

TOMORROWLAND|【別注】DIMAGLIA CRAVATTE*TOMORROWLAND カシミヤ

TOMORROWLAND|【別注】DIMAGLIA CRAVATTE*TOMORROWLAND カシミヤ

TOMORROWLAND|【別注】DIMAGLIA CRAVATTE*TOMORROWLAND カシミヤ

別注】Dimaglia Cravatte×TOMORROWLAND カシミヤシルク スカーフ

別注】Dimaglia Cravatte×TOMORROWLAND カシミヤシルク スカーフ

別注】Dimaglia Cravatte×TOMORROWLAND カシミヤシルク スカーフ

別注】Dimaglia Cravatte×TOMORROWLAND カシミヤシルク スカーフ

別注】DIMAGLIA CRAVATTE×TOMORROWLAND ニットスカーフ|TOMORROWLAND

別注】Dimaglia Cravatte×TOMORROWLAND カシミヤシルク スカーフ

TOMORROWLAND|【別注】DIMAGLIA CRAVATTE*TOMORROWLAND ニット

TOMORROWLAND|【別注】DIMAGLIA CRAVATTE*TOMORROWLAND ニット

別注】DIMAGLIA CRAVATTE×TOMORROWLAND ニットスカーフ|TOMORROWLAND

別注】DIMAGLIA CRAVATTE×TOMORROWLAND

別注】DIMAGLIA CRAVATTE×TOMORROWLAND

TOMORROWLAND|【別注】DIMAGLIA CRAVATTE*TOMORROWLAND カシミヤ

リバーシブルニットスカーフ/Dimaglia Cravatte(ディマリア

TOASTIES】ボアスカーフ|THE STORE by C'(ザ ストア バイ シー)の通販

別注】CARIAGGI×TOMORROWLAND カシミヤストール|トゥモローランド

Dimaglia Cravatte: カシミヤ シルク スカーフ: ストール/マフラー

別注】CARIAGGI×TOMORROWLAND カシミヤストール|トゥモローランド

別注】DIMAGLIA CRAVATTE×TOMORROWLAND ニットスカーフ|TOMORROWLAND

スカーフ バンダナ 【別注】DIMAGLIA CRAVATTE×TOMORROWLAND カシミヤ

TOMORROWLAND|【別注】DIMAGLIA CRAVATTE*TOMORROWLAND カシミヤ

Dimaglia Cravatte: カシミヤ シルク スカーフ: ストール/マフラー

Dimaglia Cravatte: カシミヤ シルク スカーフ: ストール/マフラー

TOMORROWLAND シルク 小紋柄ストール|TOMORROWLAND(トゥモローランド

別注】CARIAGGI×TOMORROWLAND カシミヤストール|トゥモローランド

Dimaglia Cravatte: カシミヤ シルク スカーフ: ストール/マフラー

別注】DIMAGLIA CRAVATTE×TOMORROWLAND カシミヤシルク スカーフ

別注】CARIAGGI×TOMORROWLAND カシミヤストール|トゥモローランド

リバーシブルニットスカーフ/Dimaglia Cravatte(ディマリア

リバーシブルニットスカーフ/Dimaglia Cravatte(ディマリア

別注】DIMAGLIA CRAVATTE×TOMORROWLAND カシミヤシルク スカーフ

リバーシブルニットスカーフ/Dimaglia Cravatte(ディマリア

MANNER MARKET シルク プリントスカーフ|TOMORROWLAND

楽天市場】【別注】DIMAGLIA CRAVATTE*TOMORROWLAND カシミヤシルク

別注】CARIAGGI×TOMORROWLAND カシミヤストール|トゥモローランド

商品の情報

メルカリ安心への取り組み

お金は事務局に支払われ、評価後に振り込まれます

出品者

スピード発送

この出品者は平均24時間以内に発送しています